Plan, do, check, act – the PDCA cycle

As you consider how to become a more effective manager, you might find the ‘Plan, Do, Check, Act cycle’ or PDCA framework useful to remember.

It's a straightforward approach to problem-solving and improvement that's been around for decades, yet remains relevant in today's workplace.

The meaning of PDCA

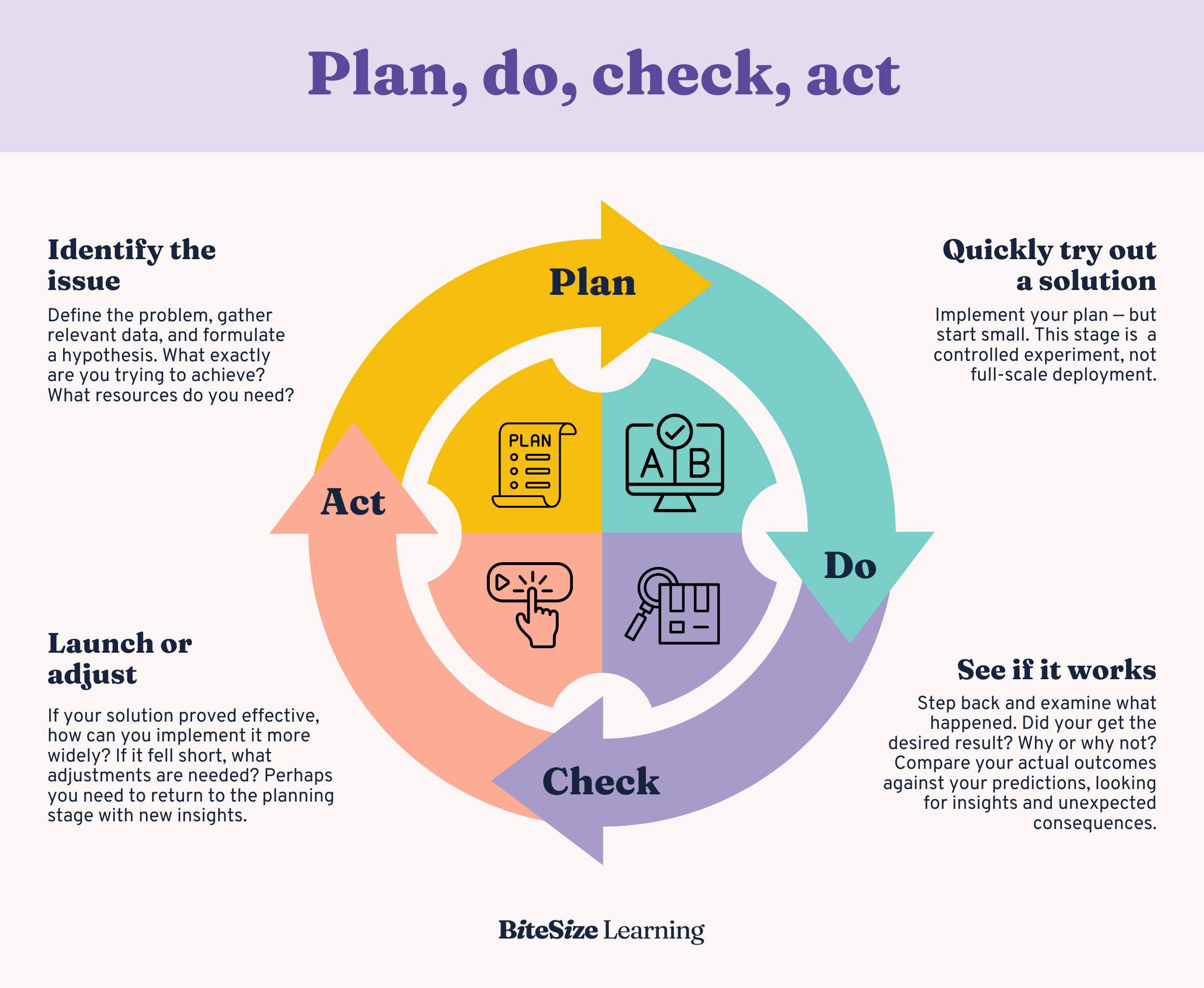

PDCA stands for Plan, Do, Check, Act. It's a four-step cycle that encourages methodical thinking and action, helping you to tackle problems systematically and drive continuous improvement. Let's break it down:

Plan: Define the problem and hypothesise a solution

Do: Implement your solution on a small scale

Check: Analyse the results of your action

Act: If successful, implement widely; if not, start the cycle again!

Sounds simple, right? It is, and that's part of its beauty. But don't let its simplicity fool you—PDCA can be a powerful tool when applied consistently and thoughtfully.

The Plan Do Check Act cycle diagram

Click image to enlarge. Right-click and Save As... to download. Just link back to his page if you use the diagram elsewhere.

The origins of PDCA

PDCA was popularized by W. Edwards Deming, the American statistician and management consultant who played a significant role in Japan's post-war economic recovery. However, its roots trace back to the scientific method and earlier iterations like Walter Shewhart's Plan-Do-Study-Act (PDSA) cycle.

You might wonder why we're still talking about a concept from the mid-20th century. The answer lies in its versatility and effectiveness. PDCA isn't tied to any specific industry or type of problem—it's a universal approach to improvement that can be applied in manufacturing, software development, personal productivity, or virtually any other domain.

PDCA in action

Let's say you're managing a team, and you've noticed that meetings often run over time, cutting into productive work hours. Here's how you might apply PDCA:

Plan: Analyze the current meeting structure and hypothesize that implementing a strict agenda and timekeeper role could improve efficiency.

Do: Try this new meeting format with one of your weekly team meetings.

Check: After a month, survey team members and analyze productivity metrics to see if the new format is working.

Act: If successful, roll out the new meeting structure across all team meetings. If not, go back to the planning stage and try a different approach.

This example illustrates how PDCA encourages you to start small, test your ideas, and refine based on real-world results rather than assumptions.

Beyond the basics: PDCA's nuances and criticisms

While PDCA is widely respected, it's not without its critics. Some argue that its simplicity can lead to oversimplification of complex problems. Others point out that in fast-moving environments, the time taken to complete a full PDCA cycle might be too long.

These are valid concerns, but they often stem from misapplication rather than inherent flaws in the model. PDCA isn't meant to be a rigid, time-consuming process. The key is to adapt the scale and speed of your PDCA cycles to your specific context.

For instance, in software development, you might complete multiple PDCA cycles in a single day as part of an agile sprint. In contrast, a manufacturing process improvement might involve PDCA cycles that span weeks or months.

PDCA and other management frameworks

PDCA doesn't exist in isolation. It shares DNA with other popular management frameworks. For example, you'll see echoes of PDCA in the Build-Measure-Learn cycle of the Lean Startup methodology, or in the iterative nature of Agile development.

You might also notice similarities between PDCA and the scientific method. Both emphasize forming hypotheses, testing them, and refining based on results. This isn't coincidental—PDCA brings scientific rigor to management and problem-solving.

Implementing PDCA in your work

As you consider incorporating PDCA into your management toolkit, remember that it's not just about following steps—it's about cultivating a mindset of continuous improvement.

Start by identifying a small, manageable problem in your work. Apply PDCA to this issue, and pay attention to how it shapes your thinking. You might find that even if your first solution doesn't work, the process itself yields valuable insights.

Also, consider how PDCA might complement your existing management practices. For instance, if you're already using OKRs (Objectives and Key Results), PDCA could provide a structured approach to achieving those objectives.

Finally, remember that PDCA is as much about learning as it is about problem-solving. Each cycle should leave you and your team with new knowledge, regardless of whether your proposed solution worked.

In an era where change is constant and adaptation is crucial, PDCA offers a timeless approach to improvement. By embracing this cycle of planning, doing, checking, and acting, you're not just solving problems—you're building a culture of continuous learning and improvement. And in today's complex business landscape, that might be your most valuable asset.

![[Guide] Handling conflict at work: what good managers do differently](https://images.squarespace-cdn.com/content/v1/6348398d9d21fd6277c64f96/1764074828110-OAKDWQ3PJ3E0VQ4BAE84/blog+images+June+2025+%2820%29.png)